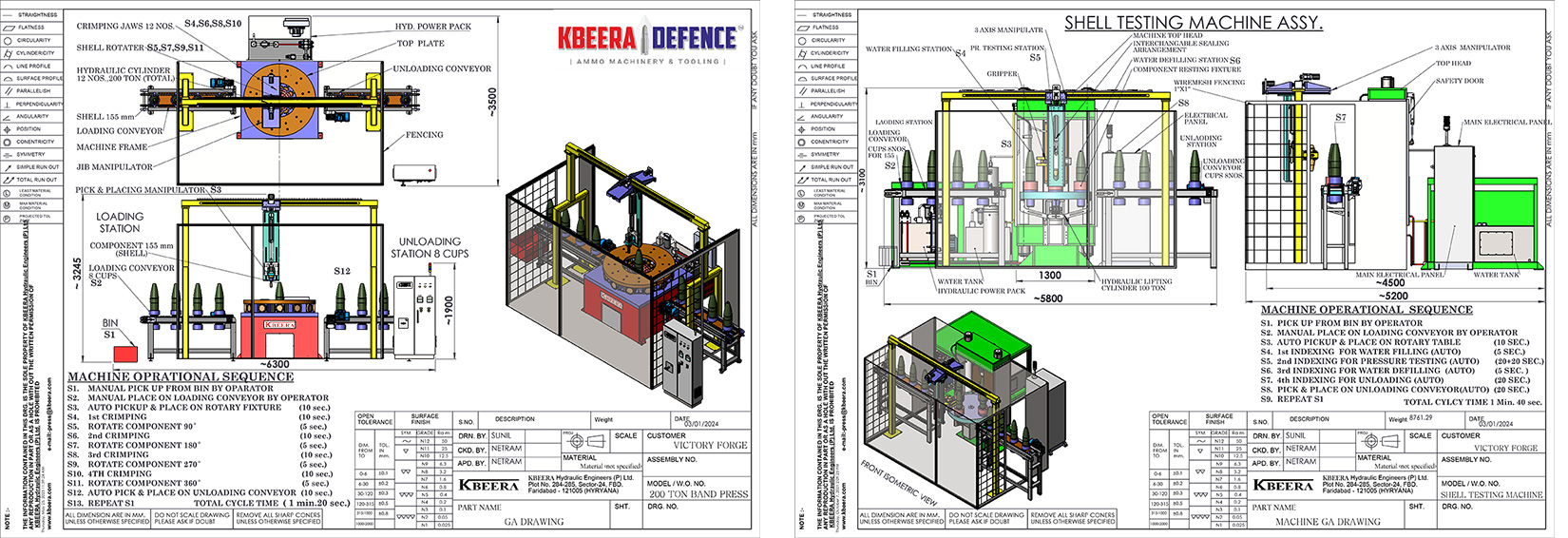

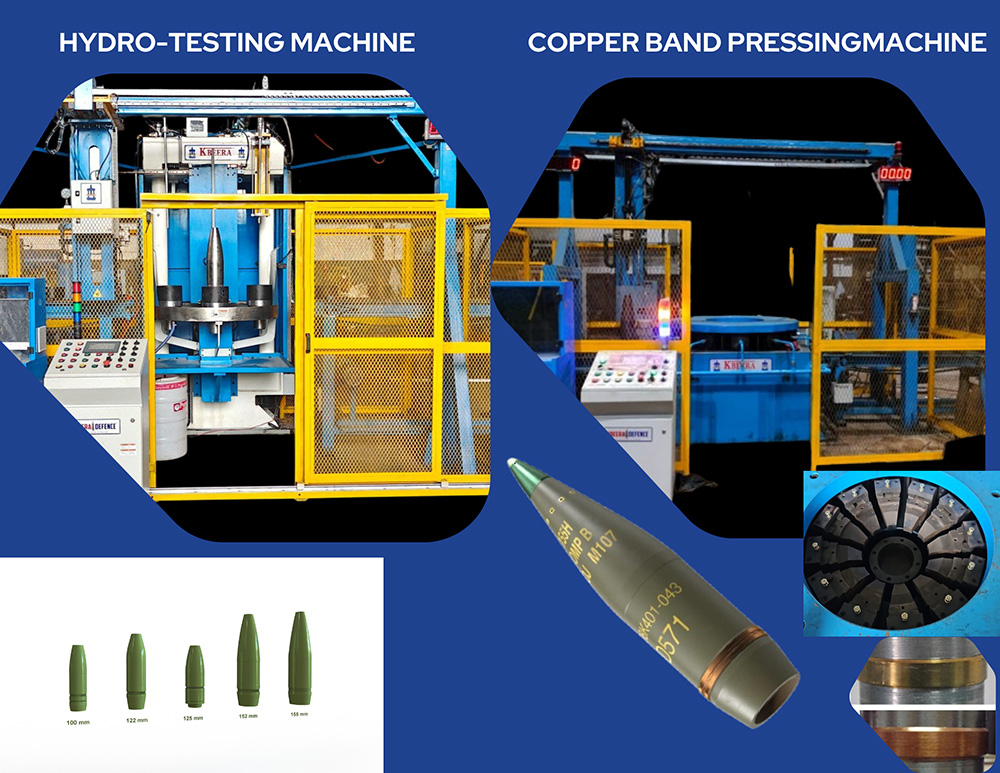

We are pioneers in designing and manufacturing artillery shell testing and band crimping machine for NATO -Standard calibres like M107, M795, M483A1 155 mm projectiles and have supplied to various government and private sectors industries. The machine is designed to test the component for its strength to withstand extreme conditions and also helps in identifying its weaknesses for further improvement. The component is tested on extreme pressure of 1200 -1800 bars depending on its parameters. Our machine is equipped with various safety features such as armoured enclosure for testing, mechanical safety, electrical safety, hydraulic safety etc.

Some of the Key Features of our Hydro-testing machine are:

- Capable of impressing rotating bands (cooper or brass rings) into groove of projectile shells

- Crimping pressure of 500 – 2000 Tons depending on the shell size

- Number of hydraulic cylenders 6-12 with indexing upto 50 times.

- Variable Diameter (100 to 200 mm) and Length (400 to 1000 mm) Bomb shells can be crimped

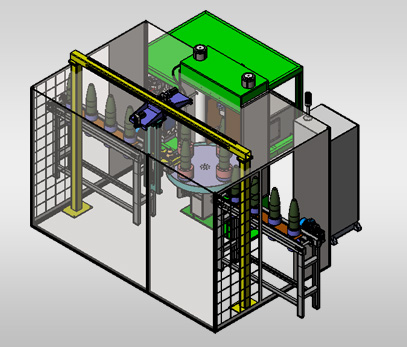

- Automatic Pick-n-Place Machine with Robot as well as manipulator depending on customer requirement. We provide complete automation

- Loading and Unloading Conveyor for automatic feeding and discharge of Shells with Poke-Yoke integration.

- Bar code marking & reading system for easy identification of the produced shells.

- OK, NG Marking Stamp on components.

- Critical parameters test report generation & backward tracking of the Shells with Laser Printing (Post Test)- Results

- SCADA control with complete process automation & graphical representation with Report generation on PC supplied with the machine.